T. Baker Smith receives Tiger Business Award

May 2, 2012

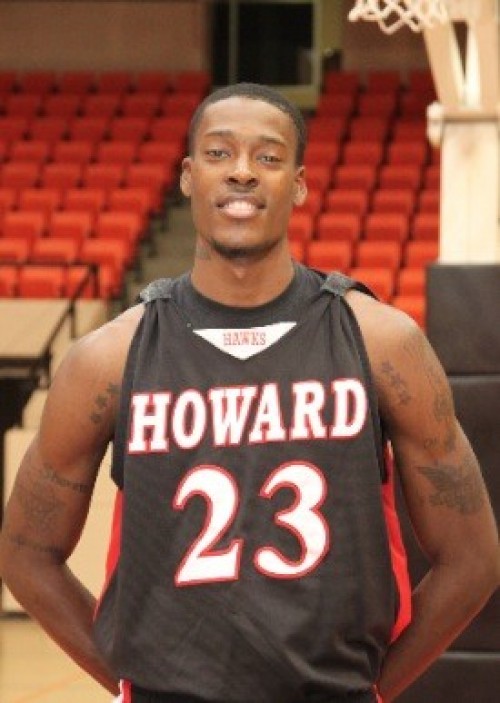

Coleman chooses LSU

May 2, 2012As a third generation proptologist, Pat “Baggy” Kelpsch knows that having a well-fitting and functioning propeller on a corresponding boat motor is like having properly tailored clothes. Not only does it look better, but the operator is able to maneuver more comfortably and confidently.

Kelpsch also knows that owning a boat in coastal Louisiana, no matter what size, make or function, holds one certainty – somewhere along the line the propeller is going to get damaged and need repair or replacement.

With his wife, Sandra, operating the front end of the small machine shop along the Intracoastal Waterway, Kelpsch said growing up in the business and keeping it a mom and pop operation offered him a hands-on education that formal training alone could not match, and business knowledge he might never have gained working for someone else.

After high school and a stint in the Air Force, Baggy Kelpsch returned to the family business in 1976. “My dad put me to work grinding one of those big propellers and I decided I’d rather work on the small ones.”

“I don’t do the big propellers for tugs and offshore service vessels,” Baggy Kelpsch said. “My brother, [Michael Kelpsch of Kelps and Will] does that. I do commercial and recreational boats from bass boats, to saltwater fishing, to mud boats. I do the little ones and he does the big ones.”

Baggy Kelpsch also prepares and restores propellers for drag racing water vessels.

A typical week at Baggy’s Propeller Repair begins with boat owners standing at his door after having damaged what makes their vessels move during weekend usage. “They might have hit trash in the water or hit landings when they pull up their boats,” Kelpsch said. By telling how damage occurs he revealed that the best spots for red fish and bass are in oyster reefs. Those areas are also the most threatening to small boats.

Damaged propellers can require repeated heating and straightening by hammer and anvil. Bushings might need to be replaced. Pitting might need to be ground out, followed by balancing and polishing. If damage is too extensive, selling a new propeller to the customer is the only answer. “We do that too,” this business owner said.

Just like different parts are designed for specific makes and model automobiles, different propellers are designed for different usages on respective products.

“You have stock props on a regular runabout boat,” the proptologist said. “Then you have bass boats that are high performance. Every propeller is different.”

It was not long ago that three primary companies ruled the market for boat propulsion. Now more than 50 companies offer greater variety, along with increased demand for knowledge regarding what prop works with a corresponding engine, and what replacements can enhance performance.

“For example, you have to know all the different rates and pitches for the different propellers,” Kelpsch said.

In the past, brass was the metal of choice for recreational and small commercial propellers. Then aluminum came to the market, but today stainless steel rules the waters because of its versatility and strength.

On the surface, propeller repair seems basic, but Kelpsch warned that what is seen on the surface does not represent the full work that is going on where the water meets the blade.

“It is hard,” he said of the work. “It is complicated because of the different varieties of boats.”

Although technology has made a way into this business in terms of tools that gauge steel or make angles more accurate, Kelpsch does not see it pushing out the need for machine shop repairs. “It is still less expensive to fix a propeller than replace it,” he said. “If the repair exceeds the cost of the prop then it is better to replace them, but that doesn’t usually happen.”

Price ranges for new propellers in the market this repairman services, start at $200 and increase to $1,000. The average propeller for a V-6 outboard engine will retail for approximately $650. Repairs to these products are much more affordable than replacement.

Keeping busy, Kelpsch notes that in the Tri-parish region, multiple boat ownership is more common than not. “In some places a person might own one boat,” he said. “Here they can have two or three boats.”

Even with high fuel prices and a tight economy, Baggy’s Propeller Repair nets an estimated $150,000 annually. “Everything is all paid for and I don’t owe anybody anything,” the business owner said of his ability to profit with a sole proprietorship shop. “But if those machines are not running and I’m not in here beating on the wheels I’m not making money. I love what I do, so I don’t plan on stopping.”

If he could have changed anything, Kelpsch said he would have taken the family business seriously at a younger age. “I was scared when I went into business by myself,” he said.

One thing Kelpsch could never change is the name attached to his business as well as himself. “Baggy” was a nickname he was given in childhood. Having two older brothers meant growing up with imperfect fitting, hand-me-down clothes were a common part of his life. The resulting appearance prompted the name.

“Everybody knows me as ‘Baggy,’” he said. “That and the marine business is in my blood. I’ve been doing it my whole life. It fits.”

Pat “Baggy” Kelpsch says fire and water might not mix, but putting heat to a damaged prop secures a repair and extends the life of this vital boat part.