Lafourche Parish Sheriff Craig Webre walking tall

May 21, 2015Breaking: Platform fire in Gulf

May 22, 2015MARINE INDUSTRIAL

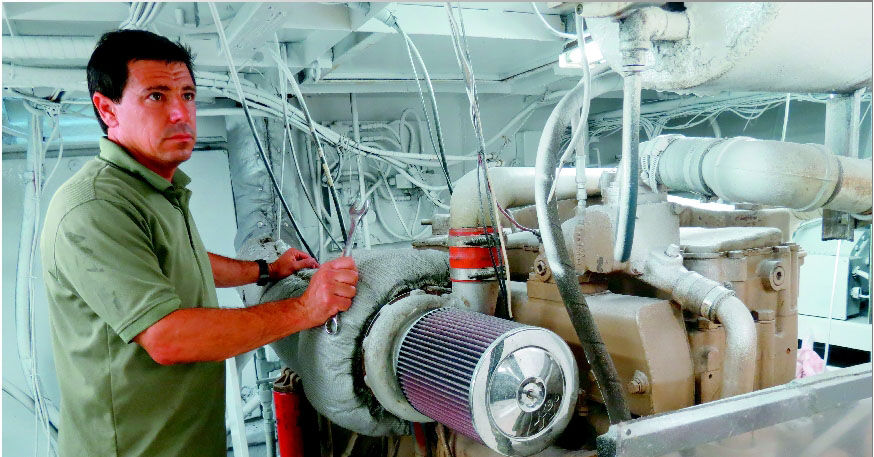

David Chauvin’s experience building boats with his father, Anthony, made the knowledge of how to perform proper maintenance and upkeep on his family’s growing fleet easier to acquire.

But that’s also meant some back-breaking work for the Bayou Little Caillou shrimper, who also owns a Dulac seafood company that bears his name.

And while he hasn’t built a boat with his own sons-Dustin and David Jr. -David did get the chance to do an overall engine replacement on his fleet’s flagship, the 73-foot trawler Mariah Jade with one of them helping out.

When the vessel headed out of port last week to begin the task of harvesting shrimp at the start of the 2015 Louisiana spring season, it was powered by a pair of Cummins 855 diesel engines, capable of 350-to-375 horsepower each.

Increasing costs of new shrimp boats, the difficulty in getting affordable materials to build one’s own and increasing regulations that can add hundreds of thousands of dollars to that process, are causing more fishermen to upgrade motors if a change is needed. For old-school shrimpers like David, nothing compares to taking problems by the horns with your own two hands and fixing them yourself.

Dustin, who normally manages dock operations at the Dulac location, was an invaluable asset, David said.

“Hours-wise we probably did it with 65 hours per engine,” David said. “We had to start from scratch, taking the old engines out, disassembling, cleaning the motor foundations down.”

The motors replaced a pair of GM-871 engines, David said, that were originally installed on the vessel. The new ones increased horsepower by 120 per engine.

The Cummins option David chose was a model that relies on fewer new technology electronics, making self-done repairs easier.

“I wanted to stay away from the electronics,” David said. “Almost every new engine has computers on the motors and I see people having trouble with the computers. Engines these days come in a tier one, two or three and the tier one, which I got, means less bells and whistles, fewer sensors.”

He related how a fisherman he is acquainted with recently lost an engine due to a lightning strike.

“The motor had to be replaced, but the old generator he had was fine and didn’t stop running,” said David.

Frugal and careful with expenses, David also said he tries to avoid having mechanics get involved.

“I don’t say ‘I need a mechanic’ I say ‘I need a part changer,”‘ David said, explaining that mechanics don’t have to diagnose, they have a machine to do that for them.

All the mechanic ends up doing, David said, is changing out a part.

But that can get expensive.

“They have a book that says how long changing a certain part should take,” David said. “It will say a job take the average person 10 hours to change it and that’s what I get billed for even if it took him six hours.”

When he has balked at this,

David said, mechanics tell him that the practice is a protection for him. If the job took 12 hours he wouldn’t be billed for that much.

“I have never seen that happen yet,” David said.

In the engine room of his trawler Mariah Jade, David Chauvin talks about the process of changing out the 73-foot boat’s two GM engines and installing two new Cummins motors. Replacing motors for greater efficiency and power, he said, will hopefully pay off.